Volvo has been using fuel injection on their cars as long as we can remember. The designs have changed over the years, but the basic idea has remained the same.

History

Volvo first used fuel injection on the P1800 series cars in 1970. Volvo used a Bosch-designed system called D-Jetronic, the injectors were electrically controlled, and the system actually had an electronic control unit. Incidentally, the “D” comes from the German word for pressure, and the “D” was added later to the original “Jetronic” name to distinguish this system from later Bosch Jetronic versions.

There was no oxygen sensor, because it had not been invented yet, but the system did use a MAP sensor that looked like something that Captain Nemo might have designed.

Some of these cars are still on the road today.

These early fuel injection systems are, obviously, a far cry from the fuel injection systems that are used in today’s cars, but some of the old designs still exist; they’re just more refined.

The main difference between the older fuel injection systems and the modern ones is the way the fuel is regulated and delivered to the combustion chamber.

In the old days, the average technician would start their fuel injection system diagnosis by looking at fuel pressure, spray patterns, and maybe even hooking up a 4 or 5 gas analyzer to the tailpipe to check the tailpipe emissions in order to diagnose fuel system problems.

These days it’s a little more complex, but we have a lot more data and tools to help us find any issues in the cars’ fuel systems.

Fuel injector problem case study: 2012 Volvo S60

This car was actually driven into a shop with a complaint of smoke coming from the exhaust and a flashing Check Engine light.

But that was only part of the story. When the customer was interviewed about the symptoms and asked how long the car had been smoking, they responded with the very common customer saying… “I’m not sure.”

When the car was started and driven into the shop, the symptoms came on right away. Not only did a massive amount of smoke come out of the tailpipe, but there was a raw fuel smell and what looked like water dripping out of the tailpipes.

The technician immediately shut off the engine and, together with the other techs, pushed the car onto a lift.

The liquid that was dripping out of the tailpipes turned out to be raw unburned fuel (YIKES!).

That meant that a lot of fuel was in the exhaust system. Think about it; look at the average exhaust system and picture the internal volume—how much fuel could it hold?

This was a big problem, because with that much fuel in the exhaust, that meant that one or more of the cylinders was probably full of fuel too.

Can you say Hydrolock?

Damage can happen in an instant, so remove the spark plugs before you try to turn over the engine.

If you continue to crank over the engine that is filling with raw fuel, hydrolock can be a real possibility, so don’t do it; you may end up bending some connecting rods.

Well, luckily for the shop and the customer, this was not the case.

Before this Volvo was worked on any further, the car was put outside to dry out. The fuel pump relay was removed and the spark plugs were removed.

Of course, the plugs were fuel fouled and the cylinders were wet with fuel, some more than others.

After you figure out what the problem is and fix it, you should always replace the spark plugs, and change the engine oil and oil filter, because the engine bearings don’t get much lubrication from gasoline.

Major bearing damage is uncommon, but you should inform your customer of the possibilities and write them up in detail on the work order, so if the engine has problems in the near future, you can cover your bases with a paper trail.

As far as the fuel in the exhaust system, after the car was parked outside for a couple of days, most of the fuel had drained out or evaporated.

The tech that was working on this Volvo started their diagnosis by using VIDA software and a laptop to connect to the car to read codes and check for any stored freeze-frame data.

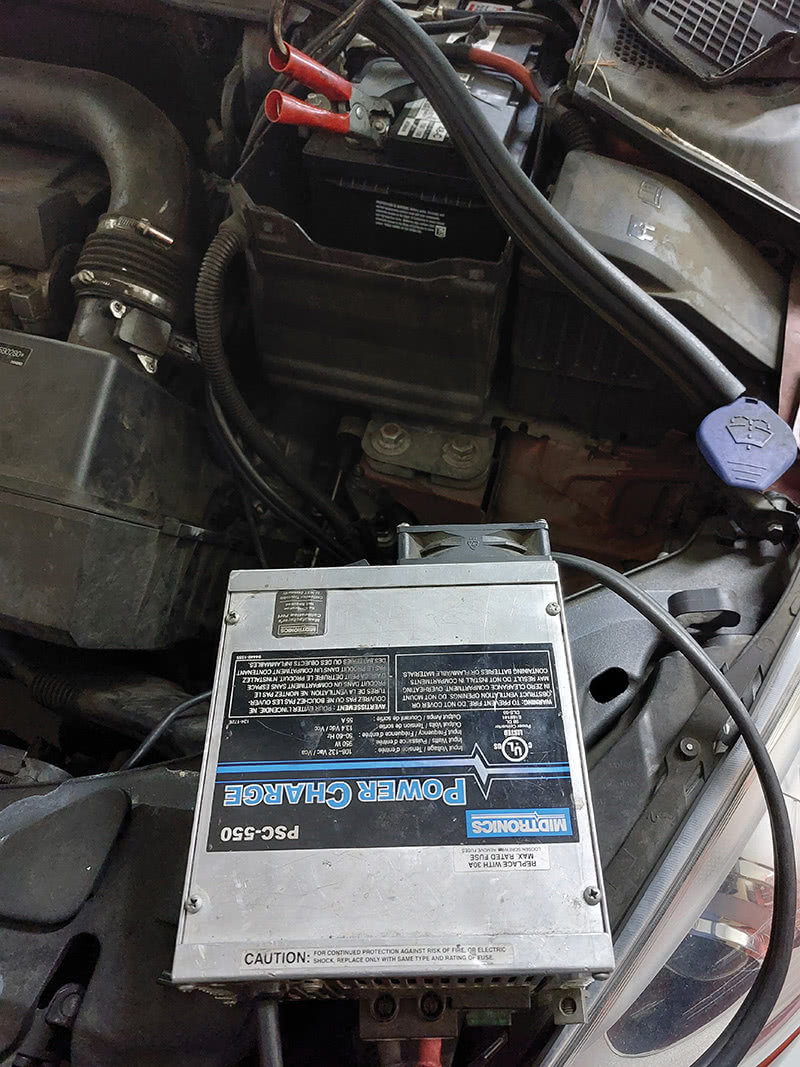

The tech also hooked up a Midtronics battery support unit to make sure that the system voltage was maintained so the test data would be accurate.

Volvo has issued a Technical Journal (TJ 16405 ) that explains the use and functions of the Midtronics battery support system.

But before the key was cycled to the On position, the tech took the precaution of removing the spark plugs to see if injectors were spraying fuel when they were not supposed to.

After all, the tech did not know what was causing the large amount of fuel to be shot into the engine.

The tech hooked up a fuel pressure gauge to the fuel rail. The fuel pressure turned out to be in the normal range at first, but with the key on and the engine off, the tech started to smell raw fuel and saw that the fuel rail’s test pressure was fluctuating and dropping.

The tech turned off the key and then used a flashlight to look into each cylinder. Cylinders 1 through 4 were dry, but cylinder number 5 had about a quarter inch of raw fuel on top of the piston.

There was obviously a problem with the number 5 injector or the signal to that injector.

The only codes stored in the ECM were for misfires. That probably rules out a signal problem, because a short or open in one of the injector circuits is a one trip fault and should set a trouble code immediately.

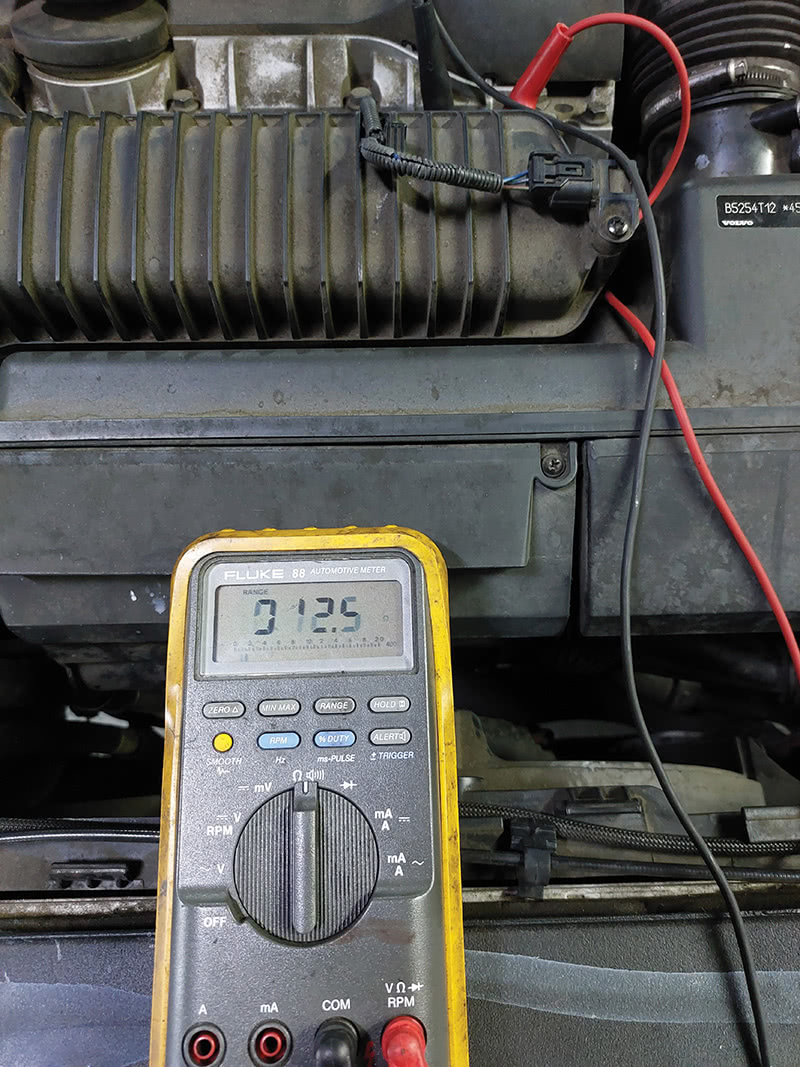

You can check the resistance of the injector with an Ohmmeter; the normal resistance specification is 12 Ohms at about 68° F, or about 20° C. (View the Volvo 2012 S60 system specs online, at: bit.ly/2012S60Spec.)

In the case of this Volvo, the bad injector had the same resistance as the new one—around 12 Ohms.

The defective injector was mechanically broken internally, allowing the injector to act like a hose nozzle.

The shop recommended that all five injectors be replaced at the same time because all the injectors were the same age and had the same mileage on them. But the customer opted to only replace the one defective injector and the oil, filter, and spark plugs, because of budget constraints.

In the case of this car, it’s important to document all findings and to explain to the customer that the over-fueling condition could have caused damage to other parts like the catalytic converter and the oxygen sensors.

The usual suspects are fuel pressure regulator, fuel injector signal problems from the ECM, or one or more faulty fuel injectors.

Let’s start with fuel pressure. The normal fuel pressure for this Volvo is 400–480 kPa.

You can use a scan tool or or Volvo’s Service, Parts and Diagnostic Application VIDA (Vehicle Information and Diagnostics for Aftersales) to read live data and see what the ECM is reporting the fuel pressure to be. But in cases like this, it’s always a good idea to verify the actual fuel pressure with a good fuel pressure gauge setup. Volvo sells a nice setup that’s available from Volvotechinfo.com or from your local Volvo retailer’s parts department.

Fuel pressure sensor

The fuel pressure data that the ECM sees is calculated by the fuel pressure sensor (or pressure control switch). This sensor is located on the end of the fuel injector common rail.

These sensors can fail over time, but they usually will cause mild symptoms like poor fuel mileage, and will usually set a specific trouble code.

If you have to replace the fuel pressure sensor, remember to relieve the line pressure before you pull off the sensor or you may get a face full of fuel.

Also, when ordering a new fuel pressure sensor, you should get the part number from the old part because there are multiple variations and all of them will fit, but not all of them will perform properly.

Pay attention to the color of the plastic on the top of the sensor; if the sensor has a black plastic top, don’t install a sensor with a gray top. The car will start and run but there will be a lack of power and it will eventually set a trouble code.

How the system checks itself: The Volvo OEM fuel Pump Electronics control Module (PEM)

The Engine Control Module (ECM) controls the fuel pressure via the fuel pump control module using a Pulse Width Modulation (PWM) signal. The fuel pump control module then controls the fuel pump depending on the pressure requested by the ECM.

The diagnostic trouble code is stored if the actual pressure (measured pressure from the fuel pressure sensor) pulses too much.

General

The PEM, or fuel pump control module, has no functions for diagnostics. Instead, fuel pressure control components and functions are diagnosed by the ECM.

The following components and functions are diagnosed by the engine control module. Diagnostic trouble codes can be stored for each component and function:

- Fuel pump control module or PEM: A diagnostic procedure checks the power supply. A diagnostic trouble code will be stored and the fuel pump will not work if there is no power supply to the fuel pump control module. The fuel pressure sensor is equipped with an integrated fuel temperature sensor; a diagnostic procedure checks the pressure and temperature signals to see if they are outside the normal operating range of the sensor.

If a fault in the fuel pressure sensor itself is detected, the fuel pump will run at a pre-defined power and the pressure is governed by the bypass valve in the fuel tank. - Fuel pressure: The engine control module compares the requested pressure with the measured pressure (signal from the fuel pressure sensor). If the measured pressure deviates excessively from the requested pressure, or if the pressure pulses, a diagnostic trouble code will be stored for incorrect fuel pressure. The comparison is not active if a diagnostic trouble code for the fuel pressure sensor is stored. A DTC for fuel pressure will be stored if there is a fault in the fuel pump.

- Communication cable: The engine cannot be started if there is a fault in the communication cable between the engine control module and the fuel pump control module. A diagnostic trouble code will be stored for the fault.

Components and functions which cannot be diagnosed: If there is a fault in the bypass valve in the tank unit, the starting process of the engine will take longer if the valve is leaking fuel when the fuel pump is off. If the valve does not open when there are pressure peaks in the fuel system, engine operation will be affected negatively, especially after engine braking. The fault can also cause rough idling.

These units rarely go bad unless the connections become corroded or loose from accident damage or rust. This can happen especially in the snow and salt states.

If you work on some of these cars, you may have seen this.

0 Comments